RFID tags are smart labels that integrate a microchip and an antenna for wireless identification and tracking of objects. They communicate with RFID readers using radio frequency signals, allowing for identification and data exchange. RFID technology offers numerous advantages, including water resistance, magnetic resistance, high-temperature durability, long lifespan, long-range reading capabilities, data encryption, large storage capacity, and flexible information updates. The emergence of this technology has brought revolutionary advancements to the field of automatic identification.

1. Chip: The chip is the core component of an RFID tag, storing the tag's unique identifier and other related data. This data can include the object’s serial number, production date, batch information, and more. Chips are usually made from semiconductor materials and have a very small size.

2. Antenna: The antenna is used to receive and transmit radio frequency signals. When an RFID tag receives the activation signal from an RFID reader, the antenna transmits this signal to the chip and also sends the data signal returned from the chip back to the reader.

3. Encapsulation Material: This material protects the chip and antenna from damage or contamination from the external environment. Encapsulation materials are typically made from plastic or other durable substances.

RFID tags can be classified based on their operating frequency into different types, including LF RFID tags, HF RFID tags, UHF RFID tags, and Microwave RFID tags. Each type of RFID tag is suitable for different applications and has varying reading distances, storage capacities, and cost characteristics.

In 1937, the U.S. Naval Research Laboratory (NRL) developed the Identification Friend-or-Foe (IFF) system to distinguish between allied and enemy aircraft. This technology later became the foundation for modern air traffic control in the 1950s and marked the early beginnings of RFID technology, which was initially applied in military and laboratory settings.

In the late 1960s and early 1970s, the Electronic Article Surveillance (EAS) system emerged as a common anti-theft solution in retail environments.

During the 1980s, RFID technology began to see early commercial applications in areas such as railroads and food tracking.

By the 1990s, small RFID tags started to be standardized, leading to the introduction of the concept of the Electronic Product Code (EPC), which aimed for the unique identification of every item globally.

RFID (Radio Frequency Identification) is a non-contact automatic identification technology that uses radio frequency signals to automatically recognize target objects and retrieve relevant data. This recognition process requires no human intervention and can operate in various harsh environments. RFID technology can identify fast-moving objects and simultaneously read multiple tags, making it quick and convenient to use.

1. RFID tags represent a groundbreaking technology with several key advantages:

2. Specific Object Recognition: RFID can identify individual, highly specific items, unlike barcodes, which can only categorize a group of items.

3. Radio Frequency Data Retrieval: RFID uses radio waves to read data through external materials, whereas barcodes require a laser for scanning.

Simultaneous Reading: RFID can read multiple objects at the same time, while barcodes can only be read one at a time. Additionally, RFID tags can store significantly larger amounts of information.

The basic working principle of RFID technology is not complicated: when a tag enters a magnetic field, it receives radio frequency signals emitted by a reader. This generates an induced current, which powers the tag to send the product information stored in its chip (in the case of Passive Tags) or to actively transmit a signal at a specific frequency (for Active Tags). The reader then decodes this information and forwards it to a central information system for further data processing.

1. Antenna: This transmits radio frequency signals between the tag and the reader.

2. RFID Tag Reader: This device reads (and sometimes writes) the information from the tags. It can be designed as either handheld or fixed.

The reader communicates using electromagnetic pulses emitted through the antenna. The transceiver receives these pulses and sends the stored information back to the reader as a response. Essentially, this enables contactless reading, writing, or deletion of data from the memory.

Technically speaking, smart tags contain an RFID circuit, which includes an RFID chip with a radio frequency component and a thin antenna loop. This antenna is embedded within the tag alongside a plastic film. Typically, a paper label is attached to the tag, allowing for the clear printing of important information. Current smart tags are generally the size of a credit card, with smaller options available at 4.5 x 4.5 cm, and circular tags with a diameter of 4.7 cm, often used on CDs and DVDs.

Compared to other ID technologies like barcodes or magnetic stripes, the advantages of transceiver technology lie in the wireless link between the reader and the transceiver. The read/write unit does not require direct line-of-sight contact with the transceiver, allowing it to be fully integrated into products. This means that transceivers are suitable for harsh environments and are resistant to moisture, dirt, and mechanical impact. As a result, RFID systems provide high reading reliability, fast data acquisition, and importantly, reduce labor and paper usage.

Inventory Management: RFID tags can be used to track items in inventory, improving the efficiency and accuracy of warehouse management. By reading the information on the tags, real-time data about the location, quantity, and other details of the items can be obtained.

Supply Chain Management: RFID technology can help businesses manage their supply chains more effectively, such as monitoring the transportation process of goods and ensuring that products arrive safely at their destinations.

Theft Prevention: Retailers can use RFID tags to prevent shoplifting. When an unauthorized person attempts to remove an item from a shelf or display case, the reader can detect the tag and trigger an alarm.

Authentication and Security: RFID tags can be used for authentication and security applications, such as access control systems, passports, and membership cards.

Healthcare: The application of RFID technology in healthcare includes patient identification, medication management, and tracking of medical equipment.

Animal Tracking and Management: RFID tags can be used to track and protect wildlife, as well as for managing livestock in agriculture.

Automotive Industry: RFID technology is applied in the automotive industry for vehicle identification, key management systems, and tracking of auto parts.

Agriculture: RFID tags can be used to track the use of crops, fertilizers, and pesticides, thereby enhancing agricultural productivity and environmental sustainability.

RFID tags come in a variety of types, each with unique characteristics and application scenarios. The following RFID tags are categorized as follows:

1. Categorized by power supply method

a. Passive tags:

Do not require a built-in power supply, relying on the reader’s electromagnetic wave for power.

Low cost, but shorter working distance.

Wide range of applications, such as logistics tracking and inventory management.

b. Active tags:

Built-in power supply, allowing the tag to actively send signals.

Long reading distance, but higher cost.

Commonly used in scenarios requiring long-distance identification, such as intelligent transportation systems.

c. Semi-active tags:

Combine the features of active and passive tags.

Internal battery powers the microchip, while communication relies on the reader’s electromagnetic waves.

Suitable for scenarios requiring mid-range recognition with relatively low costs.

2. Categorized by operating frequency

a. Low-frequency tags:

Operating frequency of 125~134kHz.

Strong penetration, suitable for animal tracking and use in liquid environments.

b. High-frequency tags:

Operating frequency of 13.56MHz.

Suitable for short-range, fast reading of multiple tags; commonly used in library management and access control systems.

c. UHF tags:

Operating frequency of 860~960MHz.

Allow long-distance, fast reading, though multi-tag environments may experience conflicts.

Widely used in logistics, warehousing, and similar fields.

3. Categorized by material and use

a. Copperplate RFID tags:

Smooth surface, capable of clearly displaying patterns and text.

Suitable for product labels, exhibition tickets, and more.

b. Thermal paper RFID tags:

Quickly print information using thermal printing technology.

Commonly used in logistics, distribution labels, and supermarket price tags.

c. PET flexible RFID tags:

High strength, good transparency, waterproof, and resistant to chemicals.

Suitable for packaging of electronic products, cosmetics, and for fixed asset management.

d. Metal-resistant RFID tags:

Designed for use on metal surfaces without affecting performance.

Includes PCB metal-resistant tags, PVC metal-resistant tags, etc., suitable for smart devices, industrial control, and other fields.

e. High-temperature resistant RFID tags:

Capable of operating in high-temperature environments.

Suitable for industrial processing, medical equipment, and other high-heat applications.

f. Flexible RFID tags:

Flexible and adaptable to irregular surfaces.

Widely used in scenarios where tags need to be applied to irregularly shaped objects.

g. Special-purpose RFID tags:

Includes RFID tie tags, RFID animal ear tags, RFID laundry tags, RFID tire tags, and more.

These tags are designed for specific applications, such as anti-counterfeiting, traceability, and medical use.

Passive RFID Tags: Passive RFID tags typically have a lifespan of 10 years or more. They are powered by an antenna that captures the radio waves sent by the reader, so they don't require batteries. This makes them longer-lasting and less dependent on the operating environment.

Active RFID Tags: Active RFID tags have a built-in battery and are typically used in applications that require long read ranges and high power. Their lifespan depends on the battery life, which is typically between 2 to 5 years. Replaceable battery tags can last longer but require regular battery replacement.

Semi-active RFID Tags: These tags combine the advantages of passive and active technologies. They are usually dormant and activated only when needed. Their lifespan is typically more than 3 years, depending on the environment and frequency of use.

1. Physical Damage: The tag may be damaged by physical factors such as impact, cuts, or pressure.

2. Operating Environment: High temperatures, low temperatures, high humidity, or strong magnetic fields can shorten the tag’s lifespan.

3. Frequency of Use: The more frequently the tag is used, the shorter its lifespan.

4. Battery Life: For active RFID tags, battery life directly affects the overall lifespan of the tag.

1. Tracking and Management of Items

By attaching RFID tags to items, the location, quantity, status, and other information of the items can be tracked in real time, enabling intelligent management of the items.

2. Logistics Transportation Control

During the logistics transportation process, RFID tags can record information such as transportation routes, speed, and whether the goods are delayed, helping companies make more accurate inventory forecasts and planning arrangements.

3. Security Management

RFID tags can be used as identification, such as for personnel access cards and vehicle passes. They can also be integrated with video surveillance, gates, and other equipment to achieve enhanced security control.

4. Asset Management

RFID tags can serve as asset identifiers, recording asset numbers, specifications, models, and other details. This helps companies track assets, perform inventory statistics, and calculate depreciation.

5. Retail Management

RFID tags are widely used in the retail industry to mark product information such as brand, price, and origin, helping businesses with inventory management and product tracking. RFID technology can also be applied in smart vending machines, unmanned stores, and other scenarios to enable automated shipping, payment, and inventory management.

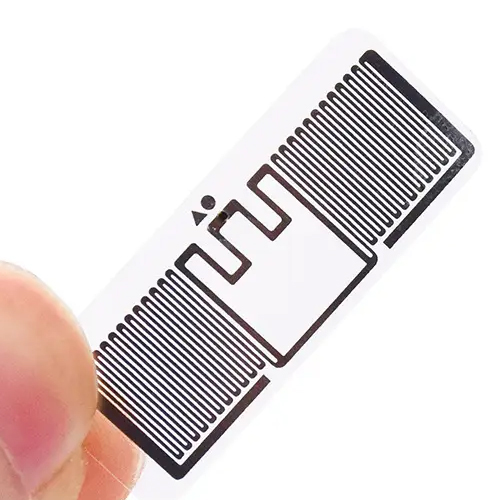

RFID tags come in various shapes, sizes, and designs depending on their application, but they typically have a few common components: an antenna and a microchip (integrated circuit). Here's what they generally look like:

1.Basic RFID Tags (Inlays):

Appearance: These are typically thin and flat. They often look like small stickers or labels with visible antenna patterns made of copper, aluminum, or silver ink.

Size: Can range from a few millimeters to several centimeters in width or length.

Use: Often embedded in product packaging, ID cards, or library books.

2. Key Fob RFID Tags:

Appearance: Look like small plastic keychains, often circular or rectangular.

Size: Similar to a keychain or small badge.

Use: Used for access control, such as for building entry systems.

3. RFID Cards:

Appearance: Similar to a credit card or ID card. The chip and antenna are embedded within the card.

Size: Standard card dimensions (about 85mm x 54mm).

Use: Access cards, payment cards, or membership cards.

4. Hard/Industrial RFID Tags:

Appearance: Enclosed in a durable plastic or metal casing. They are bulkier and designed to withstand harsh environments.

Size: Larger, sometimes several centimeters long or wide.

Use: Used in logistics, vehicle tracking, or industrial asset management.

5. Wristband RFID Tags:

Appearance: Embedded in rubber or plastic wristbands.

Size: Similar to a standard bracelet or watch strap.

Use: Common in event management, theme parks, or for patient identification in hospitals.

VS | RFID Tags | NFC Tags |

| Frequency | LF, HF, UHF (varies by application) | 13.56 MHz (HF RFID subset) |

| Range | Up to 10 meters (or more with UHF) | 4 to 10 centimeters |

| Communication | One-way (mostly), some two-way options | Two-way (read and write) |

| Common Applications | Asset tracking, inventory, logistics, etc. | Contactless payments, access control, peer-to-peer communication |

| Power Source | Passive (no battery) or active (with battery) | Passive (powered by reader) |

| Smartphone Support | Requires external RFID reader | Built-in NFC support in most smartphones |

RFID is ideal for longer-range tracking applications like inventory management, logistics, and industrial uses, where large volumes of tags need to be read over distances.

NFC, with its short-range and two-way communication, is better suited for personal and secure applications, such as payments, access control, and data exchange via smartphones.

Deactivating RFID security tags is a common task in retail environments, particularly for preventing theft. Here’s a general guide on how RFID security tags are deactivated:

1. Use of an RFID Tag Deactivator

Retailers typically use a dedicated deactivation device called an RFID deactivator or deactivator pad at checkout stations. These devices are designed to disable or remove the functionality of the RFID tag.

How it works: The deactivator emits a specific signal that either permanently disables the RFID chip or alters the tag’s frequency, rendering it unreadable by RFID readers at the store exits.

2. Deactivating Hard Tags (EAS Tags with RFID)

Electronic Article Surveillance (EAS) tags may combine RFID technology with an anti-theft mechanism like a hard plastic casing and a pin. These tags need to be physically removed using a special detacher device.

Steps:

Place the item with the hard RFID tag on the detacher (a magnetic or mechanical tool) to unlock and remove the tag.

After the tag is removed, the item is no longer detected by the store’s security system.

3. Deactivating Soft RFID Tags (Sticker Tags)

Sticker RFID tags, often found in books, CDs, or small items, are deactivated using an RFID deactivator at the point of sale.

Steps:

Scan the item as usual at the checkout.

Place the tagged item over the deactivation pad or the area marked for RFID deactivation.

The deactivator sends a signal that alters the RFID tag, making it unreadable by security gates.

4. Manually Shielding or Destroying the Tag

In certain cases, RFID tags can also be manually deactivated or destroyed by physically damaging the chip or antenna.

Methods:

Cut or break the antenna: Cutting through the RFID sticker or tag can break the circuit and stop the tag from transmitting signals.

Use RFID-blocking materials: Wrapping the tag in RFID-blocking materials like aluminum foil can block the signals, although this is a temporary solution.

5. Using an RFID Jammer (Uncommon)

An RFID jammer can emit a signal that prevents RFID readers from detecting tags within a certain range. However, this is not a legal or common practice in commercial environments, and it is not typically used for deactivation at checkouts.

Yes, RFID (Radio Frequency Identification) tags can track you, but the extent and nature of that tracking depend on several factors, including the type of RFID system in use, how the tags are implemented, and the specific context in which they are deployed. Here’s a breakdown of how RFID tags can track individuals:

1. Types of RFID Tags

Passive RFID Tags: These tags do not have a power source and rely on RFID readers for energy. They can be used for tracking items in retail or inventory management but typically have a limited range (usually a few centimeters to several meters). They can only be read when in proximity to a reader.

Active RFID Tags: These tags have their own power source and can transmit signals over longer distances (up to several hundred meters). They can be used for tracking assets, vehicles, or even people in real-time.

2. Tracking Capabilities

Location Tracking: RFID tags can be placed on personal belongings (like bags, keys, or clothing) to help track their location. For example, some companies use RFID tags in employee badges to monitor their movements within a building.

Inventory Management: In retail, RFID tags can help track items through the supply chain and in-store, allowing businesses to know when stock is low or when items are being moved.

3. Potential for Unauthorized Tracking

Surveillance Concerns: RFID technology can raise privacy concerns, as passive RFID tags can potentially be read without the owner’s knowledge. For instance, RFID-enabled credit cards or passports can be scanned by unauthorized readers if they are within range.

Data Security: If RFID systems are not properly secured, malicious actors could intercept data transmitted by RFID tags, leading to unauthorized tracking or data breaches.

4. Regulatory Considerations

Privacy Laws: Various regulations and standards address the use of RFID technology and personal tracking, focusing on ensuring that individuals are informed about data collection and have control over their information.

5. Real-World Applications

Transportation: RFID is used in toll collection systems (like EZ-Pass) to track vehicle movements without stopping.

Healthcare: Hospitals use RFID tags to track patients, staff, and equipment, which can enhance operational efficiency but also raise privacy issues.

Chipbond is a professional RFID tag manufacturer dedicated to providing customers with high quality and reliable RFID solutions. We design and manufacture a wide range of RFID products, including antennas, inlays, tags, keychains, wristbands, and wooden cards to meet the needs of different industries and applications.

With an experienced R&D team, we are able to customize our designs to meet the specific needs of our customers, ensuring that each product achieves optimal performance. We can provide personalized RFID product design services according to customers' needs to ensure that the products perfectly match the usage scenarios. We welcome customer requests for samples to evaluate the quality and performance of our products.

If you are interested in our RFID products or services, please feel free to contact us! Please send an email to info@chipbond.com and our professional team will be happy to assist you with your questions and provide you with more information.